Safe procedures for thermoplastic nano particle dispersions

Get more Details about this project at the Pitch #1

Project Description

Nano particles are known for the strong aggregates that are difficult to disperse in a thermoplastic matrix. Moreover, even as aggregates, nanoparticles may lead to airborne nanoparticles, causing concern and special requirements for the work place safety.

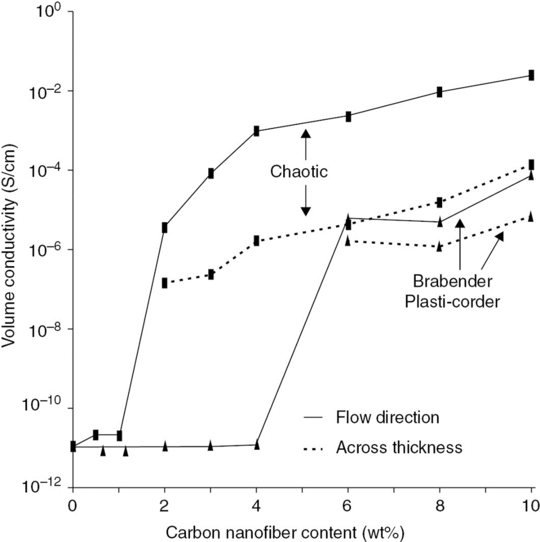

Procedures and materials which allow a safe handling and reliable dispersion of nanoparticles, in a standard compounding environment, would make nanocomposites available to a much broader range of engineering applications. Depending on the nanoparticles used, exceptional properties may be achieved, such as improved stiffness and strength with reduced density, high refractive index and/or unique thermal and electrical conductivities.

Objective: To develop a process chain ranging from the nano particle production to the processing of thermoplastic nano composites, which is limiting the work places exposed to nano particles and ensuring a reliable dispersion of nano particles in the matrix.

Timeline: A development phase of 12 to 18 months is expected to reach the objective. Following the technology development, the technology shall be transferred to high tech engineering applications.

Preliminary Poject Team

KATZ:

|

Partner Search

We are looking for:

Nano-Particle Producer:

| Nano-Analytics:

Compounder / End-user of nanoreinforced compounds |

Contact

Name ofcompany/researchinstitution | KATZ Kunststoff Ausbildungs- und Technologie- Zentrum |

Adressofcompany/researchinstitution | Schachenallee 29, 5000 Aarau |

| Website | www.katz.ch |

| Name ofcontactperson | Dr. Rémy Stoll |

| Functionofcontactperson | Managing Director |

| Telephonenumber | +41 79 759 3959 |

| remy.stoll[at]katz.ch | |

| Additional comments: | Head of aR&D: Dr. Panayota Tsotra panayota.tsotra[at]katz.ch © KATZ |