Nano-Foam-Injection-Molding

Get more Details about this project at the Pitch #1

Project Description

There are different technologies available for foam injection molding. Typical objectives of foam injection molding are weight reduction, improved filling of the mold combined with reduced shrinkage and distortion or reduced dielectric strength and lowered dielectric losses.

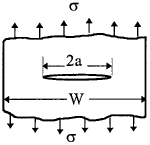

Foamed parts however experience a reduced strength due to the stress intensification around the foam cells, which is proportional to √a. Reducing the cell size by a factor of 25’000 from 250 μm to 10 nm would therefore reduce the stress intensity factor by a factor of 5’000 resulting in a strength of the foamed part, which is close to the unfoamed solid material. (top picture)

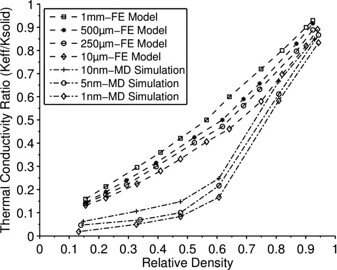

For the thermal conductivity a disruptive reduction of the thermal conductivity coefficient is reported, when reducing the cell size from 10 μm to 10 nm . (bottom picture)

Objective: A Nano-Foam Masterbatch shall be developed, that is ready to be used on standard injection molding machines, in order to produce unique thermal, mechanical and density properties of injection moulded parts for engineering applications.

Timeline: A development phase of 12 to 18 months is expected to reach the objective. Following the technology development, the technology shall be transferred to high tech engineering applications.

Preliminary Poject Team

FOAMING AGENT PRODUCER:

| KATZ:

|

Partner Search

We are looking for:

Research institution for Nano-Analytics:

| Nano-Particles:

Compounder / Foam producer / End-user of nano-foamed products |

Contact

Name ofcompany/researchinstitution | KATZ Kunststoff Ausbildungs- und Technologie- Zentrum |

Adressofcompany/researchinstitution | Schachenallee 29, 5000 Aarau |

| Website | www.katz.ch |

| Name ofcontactperson | Dr. Rémy Stoll |

| Functionofcontactperson | Managing Director |

| Telephonenumber | +41 79 759 3959 |

| remy.stoll[at]katz.ch | |

| Additional comments: | Head of aR&D: Dr. Panayota Tsotra panayota.tsotra[at]katz.ch © KATZ |