Probing Refractory Materials

05.05.2023Refractory products have a large carbon footprint and represent a significant cost factor in steel production. Therefore, the declared aim is to increase the durability of refractory products.

Knowledge of the corrosion behavior of refractory components in different slags is therefore essential and the reliable and correct determination of parameters of wear is particularly important. Within the scope of this project, an accurate and reliable determination of diffusion coefficients of refractory components in slags could be developed. For this purpose, two different measuring methods were used: a novel corrosion test and particle dissolution tests.

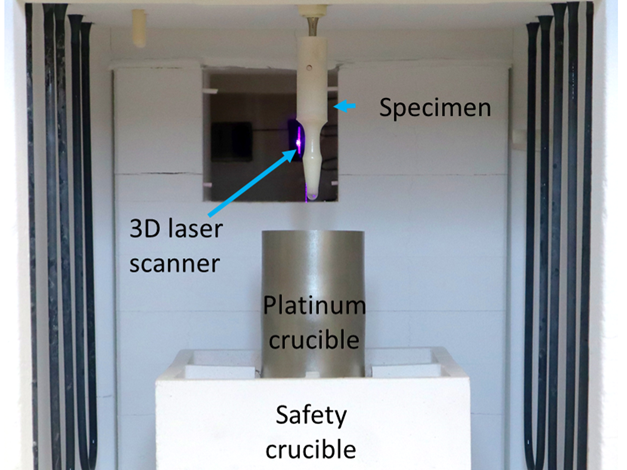

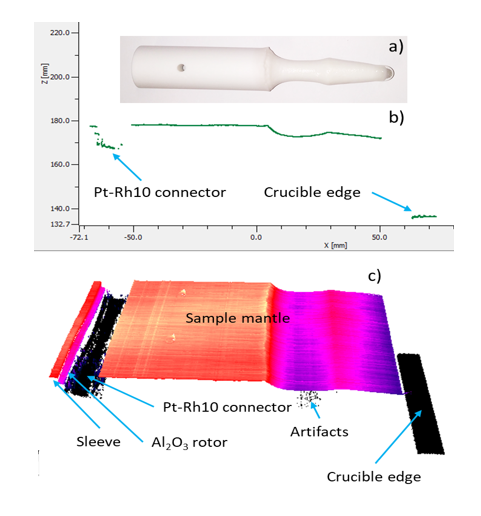

For corrosion testing at temperatures up to 1550°C a new testing device (Continuous Wear Testing Device - CWTD) has been developed. An inspection window in the furnace enables the integrated laser measurement system to automatically measure the entire 3D specimen surface at test temperature. This renders the measuring system new and unique and provides more accurate and complete data compared to the usual manual measurement of the corroded samples in the cooled state. Based on the results of these experiments coupled with computer simulations, it is possible to determine the diffusion coefficient of the examined refractory/slag system, a parameter that is significant for corrosion and an important input parameter for the computer-aided design of the lining of industrial aggregates.

For validation, the diffusion coefficient was also determined from particle dissolution experiments. Thereby, the influence of the during the dissolution moving solid/liquid boundary was taken into account which leads to a more correct determination of the coefficient values. Comparable diffusion coefficients result from both experiments.

Effects and impacts

The research activities in this project have made it possible to correctly and reliably determine diffusion coefficients of refractory components in slags. The accurate determination of characteristics for the wear of refractory materials is an essential part of the know-how and provides the basis for the design and development of improved materials.

In 2020, the market for refractory building materials was valued at around 50 million tons worldwide, with approximately 1.82 tons of CO2 emitted per ton. This shows the potential of material improvements and durability extensions to make high-temperature processes more cost-efficient, emission-reduced and resource-saving in terms of raw material consumption and waste production.

Project coordination (Story)

Dr. Sandra Vollmann

Chair of Ceramics

Montanuniversität Leoben

T +43 (0) 3842 402-3244

sandra.vollmann(at)unileoben.ac.at

IC-MPPE / COMET-Zentrum

Materials Center Leoben Forschung GmbH

Roseggerstrasse 12

8700 Leoben

T +43 (0) 3842 45922-0

mclburo@mcl.at

www.mcl.at

Project partners

• RHI Magnesita GmbH, Austria

• voestalpine Stahl GmbH, Austria

• voestalpine BÖHLER Edelstahl GmbH & Co KG, Austria

• Montanuniversität Leoben, Austria